Not known Facts About Screen Printing Custom T-shirts Abilene

See This Report on Screen Printing Custom T-shirts Abilene

Table of ContentsThe 9-Second Trick For Screen Printing Custom T-shirts AbileneSome Known Facts About Screen Printing Custom T-shirts Abilene.All About Screen Printing Custom T-shirts AbileneSome Ideas on Screen Printing Custom T-shirts Abilene You Need To KnowThe Main Principles Of Screen Printing Custom T-shirts Abilene Screen Printing Custom T-shirts Abilene Can Be Fun For Anyone

No blending required, cures incredibly rapidly, costly, ideal for detailed job. Combination of Diazo and SBQ, calls for blending, general treatment time is less than Diazo, price is reduced than SBQ. The clear acetate film is put on the emulsion-coated mesh display meticulously under an intense light which creates the emulsion to set and create.Revealing the display for a details time will solidify the exposed locations of the screen, and the continuing to be unhardened solution, if any kind of, will be washed away to leave a clear imprint on the screen. The display is then dried out, and if there are any kind of touch-ups called for, it will be done by the printer to make the imprint as near to the initial style as possible.

The product to be published is put level on the printing board, and the display in addition to the product in the wanted position, ready to be published. In this step, the published style will certainly revive. The screen is decreased to the printing board. The desired colour ink is included to the top of the display.

The ink presses with the open locations of the pattern and transfers on the underlying silk, subsequently publishing the design on the product. The stencil will certainly have served its function as soon as all the products are printed. An unique cleaning liquid is made use of to remove the emulsion to reuse the mesh for creating brand-new stencils.

Some Known Details About Screen Printing Custom T-shirts Abilene

This is done so that the style does not vanish. There are six different kinds of display printing processes. Because various techniques will certainly supply various outcomes, it is essential to understand the various kinds. The most common display printing method is spot colour display printing. Spot colour screen printing makes use of the ink's supply colour by printing it with the pattern of the mesh.

It is much simpler to use as contrasted to other display printing methods. It can be an outstanding alternative for printing on t-shirts, jackets, and hoodies.

In addition, it is a cost-effective technique since just one colour of ink is used. Grayscale printing is a superb method of printing full-colour photos as one colour grayscales or halftones.

What Does Screen Printing Custom T-shirts Abilene Do?

Duotone printing utilizes the mix of two halftones for printing the same picture with two colours. A black halftone is published with black ink, and then a 2nd halftone is printed with colour ink.

It entails the 4 standard colours cyan, magenta, yellow and black. These 4 colours are combined to create the called for colour tones. It can be done by hand yet ideally ought to be done instantly for finest outcomes. The simulated printing procedure integrates the four-colour printing procedure with area colour printing. Given that this technique serves for both lighter and find out this here darker shades, it is functional and popular with people seeking to create photorealistic print detail.

Some of these benefits consist of: One of the primary benefits of display printing is its adaptability. Contrasted to other printing methods, screen printing can use a heavy ink insurance coverage, resulting in a resilient design.

The Best Guide To Screen Printing Custom T-shirts Abilene

Screen printing is among one of the most reliable and rapid printing methods as soon as a screen has been produced. It is a superb choice if the very same style is to be published over and over once more (Screen Printing Custom T-Shirts Abilene). The display printing process is rather straightforward, whether it is automated or done by hand. The called for devices are also not difficult or pricey to replace.

Custom-made screen printing is a process that utilizes a mesh display to press ink in a predetermined layout onto the material of your choice. Screen printing is preferred for customized t-shirts, sweatshirts, jackets, and extra. Custom-made screen printed tees or various other screen-printed garments are the best way for companies to increase their brand visibility.

Little Known Facts About Screen Printing Custom T-shirts Abilene.

The ink's durability guarantees that prints endure duplicated washing and wear, making it perfect for fabrics like t-shirts, hoodies, and carryall. This method works on a vast array of surface areas, including fabrics, plastics, glass, wood, and metals. Its adaptability permits companies and creators to use layouts to products like clothing, marketing products, signs, and packaging.

Modern automated display printing press enhance the procedure, enabling higher manufacturing rates while preserving regular high quality. Automation decreases errors, making certain every print equals and as much as specialist criteria. Advancements like computer-to-screen (CTS) and direct-to-screen (DTS) modern technologies are reinventing the display printing process. These approaches remove the need for typical movie positives by electronically transferring screen printing styles directly onto the screen.

How Screen Printing Custom T-shirts Abilene can Save You Time, Stress, and Money.

While rooted in tradition, display printing has welcomed technological advancements to meet contemporary demands. Its mix of workmanship and advancement ensures it remains a top selection for innovative and commercial printing tasks. Display printing continues to be a reliable and versatile printing technique, providing lively colors and durable layouts that stick out on a selection of products.

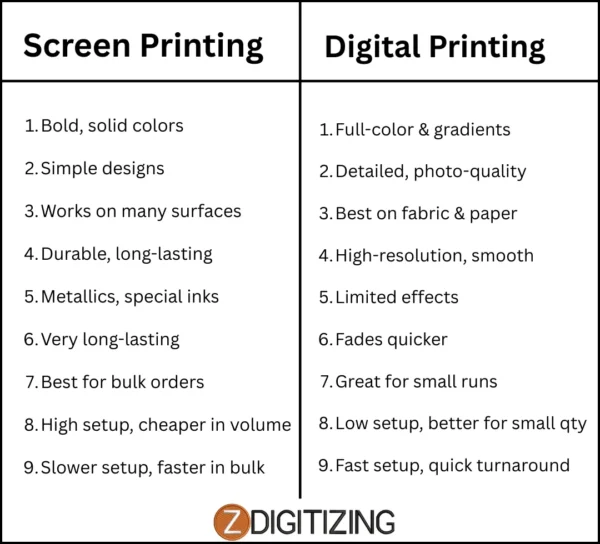

Below are several of them. Screen printing can develop a various aesthetic output when compared to electronic printing. Display printing ink is usually applied a lot more heavily, resulting in longer-lasting, brighter and more vibrant colours, also on darker histories. For garment design that needs a high level of vibrancy when publishing on dark premises, screen printing is still the very best option.

Thus higher quantities can be mass produced using display printing more quickly and more price efficiently for bigger orders. Screen printing fits a vast array of products, consisting of plastic, textile, rigid plastic, foam board, steel, glass and many others.